Login or create an account

CloseReturning Customer

I am a returning customer

Login or create an account

CloseRegister Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Thank you for registering with OPPOE - INJECTION MOLDING MACHINERY!

You will be notified by e-mail once your account has been activated by the store owner.

If you have ANY questions about the operation of this online shop, please contact the store owner.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

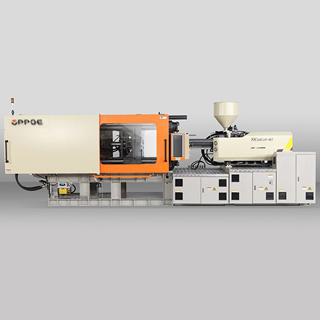

Introduce

Dear customer: In general, the following data must be paid attention to when purchasing an injection molding machine: first, the size of the mold and special requirements, and second, the characteristics of the plastic, the size, weight, number of products produced in one mold, production speed and quality Require. We look forward to the more detailed data you provide, the better. On this basis, our factory technicians can choose the most suitable model for you more accurately. We will make the right choice for you in terms of tie rod spacing, mold opening stroke, mold clamping force, injection pressure, injection volume, injection speed and plasticizing ability. Thank you for your purchase and trust!

Technicaal Parametor Tadie:

|

型号Model 项目 Item |

OP50 |

OP63A |

OP63B |

OP125 |

||||

|

A |

B |

A |

B |

A |

B |

|||

|

Injection System |

螺杆直径 Screw Diameter |

mm |

25 |

30 |

35 |

35 |

40 |

42 |

|

射出压力 Injection Pressure |

mpa |

200 |

140 |

110 |

150 |

150 |

140 |

|

|

理论射出容量 Theoretical Shot volume |

cm² |

54 |

78 |

110 |

110 |

145 |

155 |

|

|

射出量(P.S) Max.Shot Weight |

g |

45 |

60 |

75 |

75 |

130 |

135 |

|

|

射出速率 Injection Rate |

g/s |

50 |

72 |

75 |

75 |

105 |

120 |

|

|

温控区 Temperature Control |

ZONE |

2+1 |

3+1 |

3+1 |

3+1 |

|||

|

螺杆转速 Screw Speed |

r/min |

0~200 |

0~200 |

0~200 |

0~180 |

|||

|

Clamping System |

锁模方式 Clamping Means |

斜排内翻双曲肘 |

||||||

|

合模力 Clamping Force |

T |

50 |

50 |

65 |

80 |

|||

|

模板尺寸 Plater Size |

mm |

445x350 |

445x350 |

470x370 |

520x400 |

|||

|

拉杆间距 Distance Between Tie Bar |

mm |

300x200 |

300x200 |

330x220 |

365x245 |

|||

|

容模 Fired Molds |

mm |

100x300 |

100x300 |

100x320 |

100x330 |

|||

|

开模行程 Molds Opening Stroke |

mm |

200 |

200 |

230 |

320 |

|||

|

最大开模距 Max Open Daylight |

mm |

500 |

500 |

550 |

650 |

|||

|

顶出力/行程 Ejector Force/Ejector Stoke |

T/mm |

2.0/50 |

2.7/50 |

2.8/50 |

2.8/60 |

|||

|

Hydraulic Pressure and Power system |

最大液压 Max Hydaulic Pressure |

Kg/cm² |

100 |

100 |

140 |

140 |

||

|

作动油量 Pump Output |

L |

98 |

98 |

125 |

150 |

|||

|

油泵电机 Pump Motor Power |

Kw |

4 |

5.5 |

5.5 |

7.5 |

|||

|

电热容量 Barrel Heating Power |

Kw |

2.8 |

4.8 |

4.8 |

6 |

|||

|

总用电量 Total Weight |

Kw |

6.8 |

10.3 |

10.3 |

13.5 |

|||

|

Cothers |

机器重量 Machine Weight |

T |

0.9 |

1.0 |

1.15 |

1.35 |

||

|

机器外型尺寸 Machine Dimensions |

mm |

1350x1000 x1950 |

1350x1000 x2050 |

1450x1120 x2050 |

1450x1150 x2600 |

|||

OPPOE reserves the right to update product design and specifications without notice.

Respected customer: In general condition, much attention should be paid to the following data when you choose and purchase injection molding machine: the first is the size of mold and special requirement. The second is characteristics of plastic, size and weight of product, how much products can be produced in one mold, productive speed and quality requirement. We expect that it is better for data provided by you in details. On the basis, technicians of our factory can choose optimum machine exactly for you.We can also make correct selection for you in many fields, for example: distance between tie bars, opening stroke, mould clamping force, injection pressure, injection volume, injection rate and plasticizing capacity. Thank you for your choosing and trust!

|

OP250 |

OP 350 |

OP -600 |

OP -45Y |

OP -63Y |

OP -100Y |

OP -250Y |

OP-600Y |

|||||||

|

A |

B |

A |

B |

A |

B |

-- |

A |

B |

A |

B |

A |

B |

A |

B |

|

45 |

50 |

50 |

55 |

55 |

60 |

25 |

25 |

30 |

35 |

40 |

45 |

50 |

55 |

60 |

|

140 |

113 |

130 |

110 |

121 |

102 |

110 |

180 |

144 |

146 |

130 |

140 |

113 |

121 |

102 |

|

250 |

350 |

350 |

430 |

480 |

565 |

49 |

50 |

63 |

75 |

105 |

250 |

350 |

480 |

565 |

|

232 |

327 |

327 |

360 |

435 |

510 |

45 |

49 |

56 |

92 |

115 |

320 |

327 |

435 |

510 |

|

135 |

145 |

145 |

185 |

174 |

205 |

32 |

42 |

55 |

85 |

105 |

135 |

145 |

174 |

205 |

|

3+1 |

3+1 |

4+1 |

2+1 |

2+1 |

3+1 |

3+1 |

4+1 |

|||||||

|

0~160 |

0~160 |

0~160 |

0~200 |

0~200 |

0~160 |

0~160 |

0~160 |

|||||||

|

|

直压锁模 |

|||||||||||||

|

120 |

140 |

150 |

15 |

30 |

45 |

100 |

145 |

|||||||

|

610x460 |

670x515 |

830x630 |

425x290 |

520x370 |

585x435 |

735x570 |

860x660 0x660 |

|||||||

|

445x300 |

500x335 |

600x400 |

280x150 |

355x205 |

400x250 |

490x330 |

600x400 |

|||||||

|

100x400 |

100x450 |

150x500 |

40x100 |

100x160 |

150x200 |

250x300 |

300x350 |

|||||||

|

320 |

350 |

350 |

160 |

180 |

200 |

250 |

300 |

|||||||

|

720 |

800 |

850 |

260 |

340 |

350 |

500 |

650 |

|||||||

|

2.8/90 |

4.0/90 |

4.0/80 |

1.3/35 |

1.3/40 |

1.3/40 |

2.5/80 |

4.0/80 |

|||||||

|

140 |

140 |

140 |

140 |

140 |

140 |

140 |

140 |

|||||||

|

190 |

220 |

250 |

80 |

160 |

180 |

200 |

250 |

|||||||

|

11 |

11 |

15 |

3 |

5.5 |

5.5 |

11 |

15 |

|||||||

|

7.5 |

9 |

12 |

2 |

2.7 |

6 |

7.5 |

12 |

|||||||

|

18.5 |

20 |

27 |

5 |

6.7 |

11.5 |

18.2 |

27 |

|||||||

|

1.65 |

2.35 |

3.5 |

0.75 |

1.1 |

1.3 |

2.5 |

3.5 |

|||||||

|

1700x1180 x2880 |

1800x1250 x2980 |

1900x1600 x2950 |

1250x850 x2300 |

1600x1000 x2300 |

1700x1025 x2350 |

1700x1300 x2550 |

1900x1500 x2850 |

|||||||